Kraft’s dissolved pulp factory FSC in Thurso produces specialized cellulose for the textile industry. The dough is produced in reactors from wood chips transported by conveyors. For some time, a problem had been observed when filling chips: the pressure in one of the reactors suddenly increased, causing gas and chips to be pushed outwards. During these events, operators had to stop filling for a while, resulting in significant time losses.

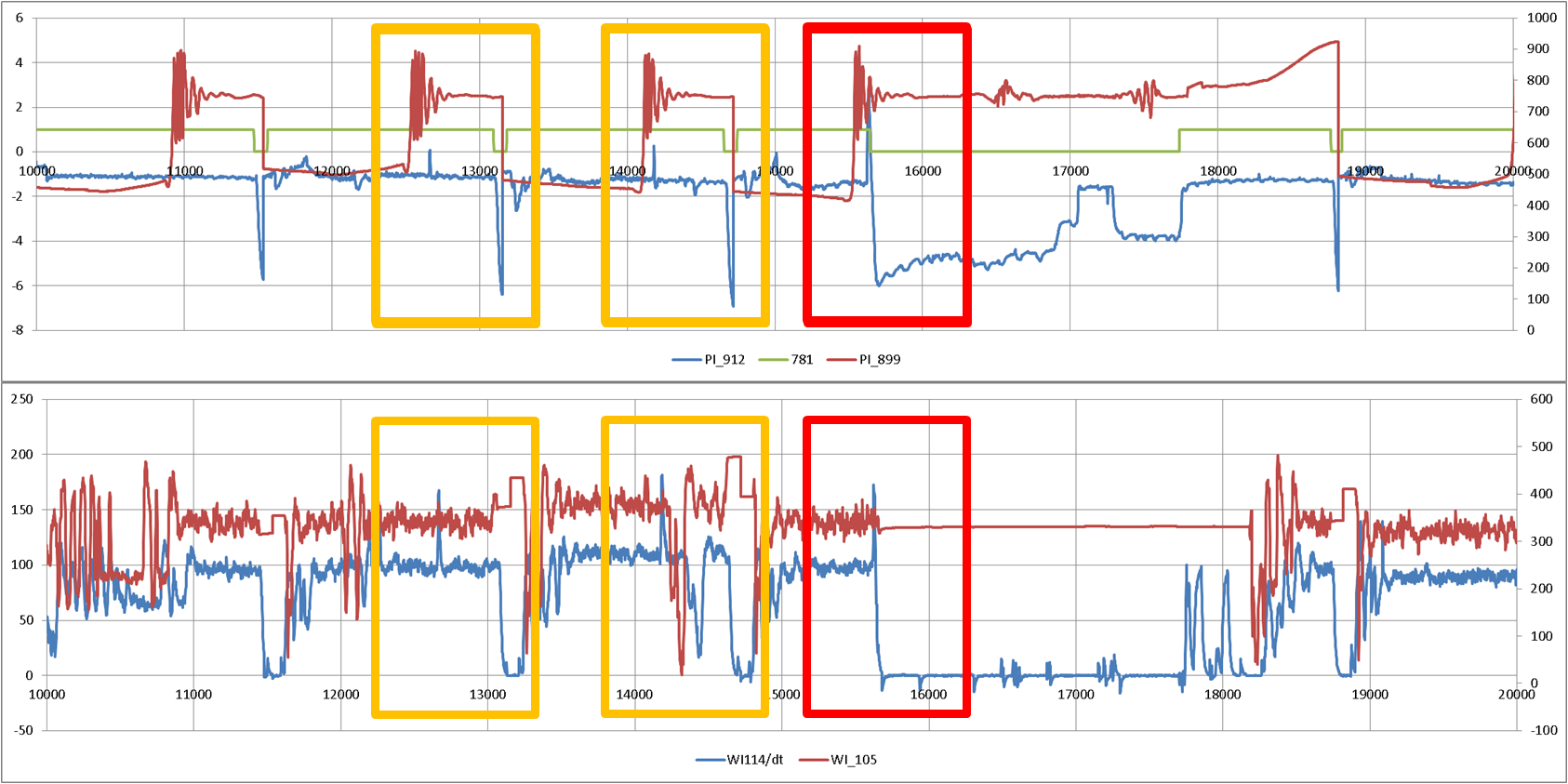

3E Eng. has been mandated to provide data analysis services to assist the plant’s technical experts in diagnosing the problem. The study of data from multiple sensors confirmed one of the hypotheses of the technical managers of the department. There were two defective valves (in series) that let a high-temperature cooking liquor pass through the reactor. When the liquor arrived at the atmospheric pressure reactor, it vaporized, causing the pressure spikes. This confirmation of the problem allowed targeted maintenance work to be carried out quickly to correct the problem.